The Inventory Problem Was Never About Stock. It Was About Decisions.

Every retail and e-commerce leader has faced this paradox:

- Best-selling products go out of stock

- Slow-moving items pile up in warehouses

- Discounts erode margins

- Forecasts look perfect on dashboards, yet reality disagrees

This is not a data problem.

It is a decision intelligence problem.

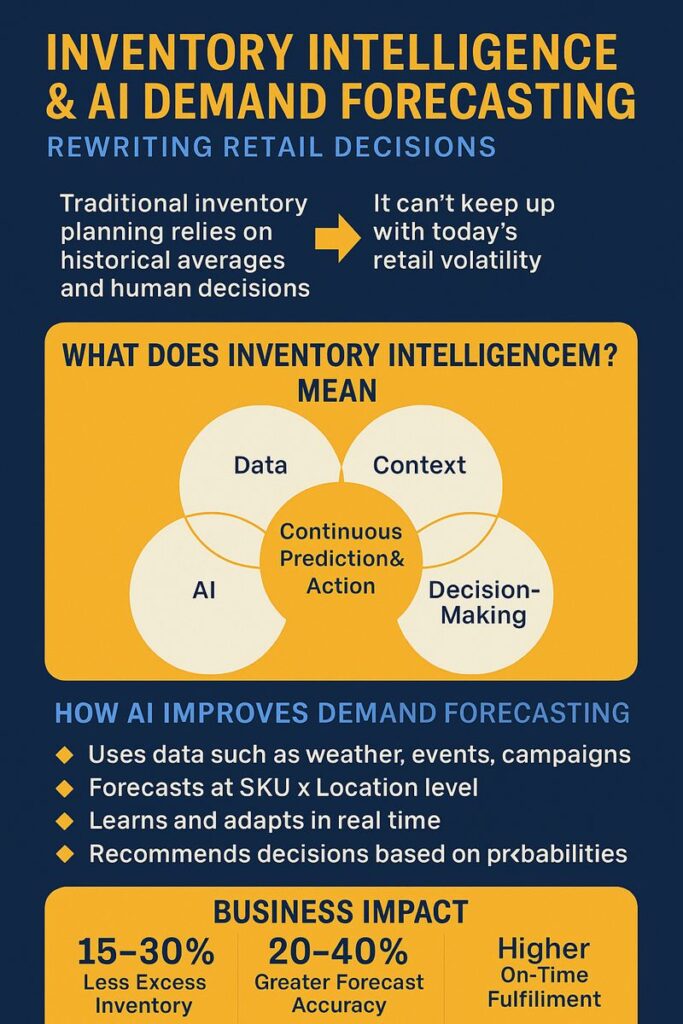

For decades, inventory planning relied on historical sales, static rules, and human judgment layered on spreadsheets. That approach worked when markets were stable, channels were limited, and customer behavior was predictable.

That world no longer exists.

Today, demand is volatile, channels are fragmented, and customer expectations change weekly. Inventory decisions must now be dynamic, predictive, and autonomous.

This is where Inventory Intelligence & AI-driven Demand Forecasting fundamentally change the game.

Why Traditional Inventory Planning Fails at Scale

Most enterprises still rely on:

- Historical averages

- Manual overrides

- Monthly or quarterly planning cycles

- Human-driven replenishment decisions

At scale, these methods break down for three reasons:

1. Historical data no longer predicts future behavior

Festivals, promotions, weather events, viral trends, and regional disruptions make last year’s data unreliable.

2. Humans cannot process multidimensional signals

Price sensitivity, location, channel mix, fulfillment constraints, and marketing activity interact in ways spreadsheets cannot model.

3. Reaction time is too slow

By the time humans detect overstock or stockouts, the financial damage is already done.

Inventory planning must shift from reactive reporting to predictive intelligence.

What Inventory Intelligence Really Means (Beyond Forecasting)

Inventory intelligence is not just “better forecasting”.

It is the ability to continuously sense, predict, and act on demand signals across the supply chain.

Inventory Intelligence =

Data + AI + Context + Autonomous Decision-Making

It answers questions like:

- What will sell, where, and when?

- What should be stocked, reduced, or rerouted right now?

- What risks are emerging before they show up in sales numbers?

This turns inventory from a cost center into a strategic advantage.

The Role of AI in Modern Demand Forecasting

AI transforms forecasting in four critical ways:

1. Multi-signal demand prediction

AI models ingest signals such as:

- Sales velocity

- Weather data

- Promotions & campaigns

- Regional events

- Online search trends

- Supply constraints

Instead of one forecast, AI produces probability-based demand ranges.

2. Granular forecasting at SKU-location level

Traditional models forecast at category or region level.

AI forecasts at SKU × store × channel × time.

This precision enables smarter replenishment and allocation.

3. Continuous learning

AI models adapt in near real time as patterns change, unlike static forecasts updated monthly.

4. Autonomous recommendations

AI does not just predict demand. It recommends:

- Replenishment quantities

- Inventory redistribution

- Markdown timing

- Supplier prioritization

In advanced setups, these actions execute automatically.

Inventory Planning: Old Model vs AI-Driven Model

| Aspect | Traditional Planning | AI Inventory Intelligence |

|---|---|---|

| Forecast Basis | Historical averages | Multi-signal prediction |

| Update Frequency | Monthly / Quarterly | Continuous |

| Decision Maker | Human planners | AI + human oversight |

| Accuracy | Moderate, brittle | Adaptive, resilient |

| Response Time | Slow | Near real-time |

| Scalability | Limited | Enterprise-scale |

Real-World Enterprise Use Cases

1. Preventing Stockouts in High-Volatility Categories

AI detects rising demand patterns early and reallocates inventory across regions before stockouts occur.

2. Reducing Overstock Without Blanket Discounts

Instead of broad markdowns, AI identifies:

- Which SKUs need discounts

- Where

- At what price point

Preserving margins while clearing excess stock.

3. Smarter Supplier Planning

Forecast intelligence feeds upstream into procurement, enabling better supplier negotiations and reduced lead-time risks.

4. Omnichannel Inventory Optimization

AI balances inventory across online, store, and fulfillment centers to avoid channel cannibalization.

Business Impact That Actually Matters

Enterprises adopting AI-driven inventory intelligence typically see:

- 15–30% reduction in excess inventory

- 20–40% improvement in forecast accuracy

- Higher on-time fulfillment

- Lower working capital locked in stock

- Improved customer satisfaction

More importantly, leaders gain confidence in decisions, not just dashboards.

The Technology Stack Behind Inventory Intelligence

A modern setup includes:

- Unified data layer (sales, supply, logistics, marketing)

- AI forecasting models

- Real-time inventory visibility

- Decision engines (recommendation + execution)

- Human-in-the-loop governance

This architecture replaces static planning tools with living systems.

Common Mistakes Enterprises Make

- Treating AI as a forecasting add-on, not a decision system

- Feeding poor-quality or siloed data into models

- Expecting instant perfection instead of gradual learning

- Ignoring change management for planners and ops teams

Inventory intelligence is as much organizational transformation as it is technology.

What Leaders Should Do Now

- Identify high-impact inventory pain points

- Start with predictive forecasting pilots

- Integrate AI insights into planning workflows

- Redesign roles from “planners” to “decision supervisors”

- Measure success by outcomes, not reports

The Future: From Forecasting to Autonomous Inventory (2026–2030)

The next phase is self-running inventory systems where:

- AI senses demand

- Predicts outcomes

- Executes actions

- Escalates exceptions to humans

The question will no longer be:

“Can we forecast demand?”

But:

“Why is this inventory decision waiting for human approval at all?”

Conclusion: Inventory Is Becoming an Intelligence Function

Inventory management is no longer about counting stock.

It is about anticipating reality before it happens.

Enterprises that adopt inventory intelligence will:

- Move faster

- Waste less

- Serve customers better

- Build resilience into their supply chains

Those that don’t will continue reacting to problems after they occur.

In modern retail and e-commerce, prediction beats reaction every time.